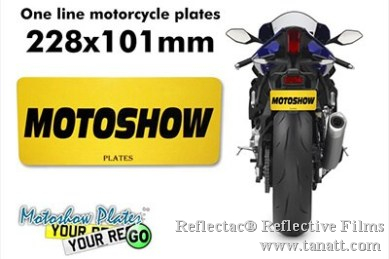

Economic License Plate Reflective Films

Face Film: Acrylic

Film Thickness: 110 mics

AVG(RA): ≥15 CIL/㎡

Durability: 3 years Outdoor

Tensile rate: >=130%

Strength: >=20N

Feature: Hot stamping, embossing, multi-color print

Car License Plate Reflective Sheeting TN9025

TN9025 Number plate reflective sheeting is a durable, all-weather, enclosed glass beaded retroreflective sheeting made with PMMA resin. It is designed for a security license plate with means to reflect the headlights of vehicles approaching the one carrying the plate. The film is embossable and can be hot stamping and roll coated with either transparent or opaque roll coating inks, also the film with watermark printing is preventing the fraud.

Lower retroreflection with an economic price for the plate that not regulated by the government.

Technical Data

- Retroreflective Elements: enclosed glass beaded

- Durability: 3 years outdoor by the specialist application (under vertical outdoor exposure)

- Roll Sizes: 1.24M (W) x 45.7M, 48” (W) x 50 yards

- Coefficients of Retroreflection (Ra)

| Obs. Angle | Ent. Angle | White |

|---|---|---|

| 0.2 | -4 | 15 |

* Test by Roadmaster according to ASTM D4956

- Film Thickness: 110 mic

- Face Film: Acrylic

- Adhesive: 30 mics permanent pressure sensitive adhesive

- Release Liner: 130 GSM Poly coated paper liner (white or yellow)

- Application Surface: Flat surface only such as aluminum

-

Application Temperature: 18-28℃ by any of the following methods:

- Mechanical squeeze roll applicator

- Hand squeeze roll applicator

- Hand application is recommended for copy only

Leading Time

- We have regular stock in the warehouse, otherwise, it will take 7-10 days upon deposits receive. Please confirm with us before ordering.

OEM & ODM

- For order less than 100 rolls, we can do OEM Carton and Product mark

- For order more than 100 rolls, and request your own logo, it needs one more deposit.

Quality Inspection

- Raw material inspection: From face film to release paper, all the material will be strictly inspected before putting into production. We only use Qualified raw materials;

- Production inspection: QC will cut production samples, bring it to our own lab then inspect brightness, stretch, thickness, etc.,also they will bring Brightness detector to production line and check for brightness.

- Final inspection:We will sample test the final product, and also do inspection under client’s requested.

Package

- Inner packing: PET inner film + Plastic Bag + 2 pc Plastic Plug

- Outer packing: 5 layers carton box with carton sealing nail

| Model | Size (M) | Carton (M) | N.W. (KG) | G.W. (KG) | 20GP (Roll) |

|---|---|---|---|---|---|

| TN9025 | 1.24*45.7 | 1.31*0.21*0.24 | 20.8 | 24.2 | 360 |

- *This data only for reference

- *Please contact our staff for customized products.

- *The data does include the pallet size, we recommended increasing the pallet to protect the goods.

- Loading Port:Shenzhen or other China port

Storage

- Reflective Sheeting must be used within 1 year after the date of receipt from Tanatt;

- Please use PET inner film to tightly packed partially used Rolls, then return it back to the shipping carton. Vertically placed it can avoid distortion due to substrate buckling or extension due to moisture absorption, and avoid pressure that may damage the reflective layer.

- Store the sheeting in a clean, dry area at 20 ℃ and 50% relative humidity and away from direct sunlight;